-

No Sectors Found

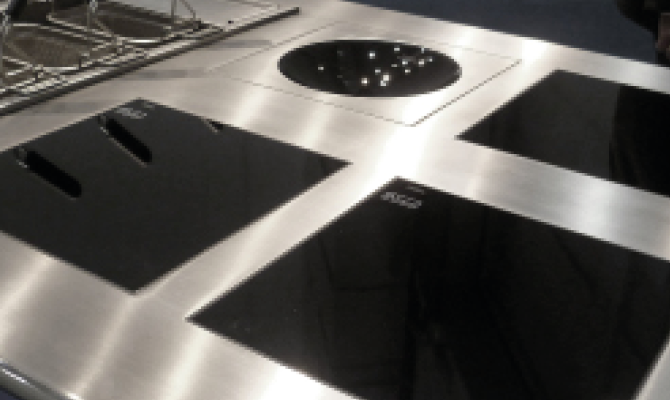

Vitroheat Radiant Heaters

For Under Ceramic Glass and Metallic Cooking Surfaces

Our experience with these type of radiant heaters dates back 25 years, both in the high volume, automated manufacturing and specialist hand-made environments. We have a detailed knowledge of the design, materials and process technologies associated with these products typically for the high-end domestic, professional and commercial cooking sectors.

Open coils fixed to high temperature microporous insulation for which patterns are carefully designed for optimum heat transfer and uniformity of thermal distribution.

These can be zoned with different circuits to optimise matching of different cookware

For higher temperature cooktop heaters, maximum top surface temperatures 600⁰C, we incorporate rod temperature limiters.

Typical lead time for samples to new design 2-3 weeks, supported by rapid prototyping via in-house CNC machining of thermal insulation and laser cut metalwork.